The oil filter is the first line of defense! Maintaining the health of internal combustion engines is crucial for the automotive industry

The oil filter is the first line of defense! Maintaining the health of internal combustion engines is crucial for the automotive industry

The oil filter is a crucial component in the automotive industry, playing a vital role in the health and lifespan of internal combustion engines. As automotive technology continues to advance and performance improves, it becomes even more important to efficiently filter engine oil. This article aims to comprehensively discuss the basic principles, design, materials, and functions of engine oil filters. Understanding the basic concepts of these filters is crucial for ensuring optimal engine performance, reducing wear, and extending engine life.

There are pollutants and impurities in the engine lubricating oil, and the oil filter is mainly used to remove them. When the engine starts, there will be friction and heat, which will cause the engine oil to decompose, and particles such as dirt, dust, metal shavings, and coal smoke will accumulate. If these pollutants are not cleaned thoroughly, the engine components will wear out more severely, fuel efficiency will decrease, and in severe cases, the engine may even malfunction. The oil filter is the first line of defense against these negative effects.

There is a key issue in the automotive industry, which is to ensure the health of internal combustion engines. So, what is the purpose of oil filters?

The filtration efficiency and overall performance of the oil filter depend heavily on the filter medium. There are several commonly used filter media, each with its own advantages and disadvantages. Traditional oil filters use cellulose filtration media, which has a good filtration effect but limited capacity and efficiency. Synthetic media such as microcrystalline glass and synthetic fibers have higher filtration efficiency, stronger pollutant holding capacity, and longer service life.

The bypass valve is a safety device that allows oil to bypass the filter when the flow rate is too fast or the filter is clogged. In this way, even if the filter is clogged, the engine will not run out of oil. There is also an anti backflow valve, which can prevent the oil from flowing back into the engine when it is turned off, ensuring that the engine is lubricated as soon as it is started and reducing engine wear. How long the engine oil filter can last is related to many factors, such as how the filter is designed, the quality of the filtered material, and the working environment.

Manufacturers usually provide specific intervals for changing oil and filters, which depend on the vehicle and its intended use. Regular maintenance, such as timely replacement of filters, is crucial for ensuring optimal engine performance and preventing damage caused by oil pollution. The oil filter is an essential component for the healthy and efficient operation of internal combustion engines. Their structure, design, filter media type, and filtration mechanism all play an important role in removing pollutants from engine oil.

The bypass valve is a safety device that allows oil to bypass the filter when the flow rate is too fast or the filter is clogged. In this way, even if the filter is clogged, the engine will not run out of oil. There is also an anti backflow valve, which can prevent the oil from flowing back into the engine when it is turned off, ensuring that the engine is lubricated as soon as it is started and reducing engine wear. How long the engine oil filter can last is related to many factors, such as how the filter is designed, the quality of the filtered material, and the working environment.

Manufacturers usually provide specific intervals for changing oil and filters, which depend on the vehicle and its intended use. Regular maintenance, such as timely replacement of filters, is crucial for ensuring optimal engine performance and preventing damage caused by oil pollution. The oil filter is an essential component for the healthy and efficient operation of internal combustion engines. Their structure, design, filter media type, and filtration mechanism all play an important role in removing pollutants from engine oil.

If the engine oil filter can operate efficiently, it can help the engine maintain the best temperature, prevent thermal stress on engine components, and improve overall engine efficiency. If the engine oil is clean, friction and wear will decrease, thus improving fuel efficiency. The engine oil filter can remove pollutants and maintain just the right lubrication, which reduces internal friction and makes the engine run more efficiently. The improvement in fuel efficiency not only benefits vehicle performance, but also reduces fuel consumption and emissions.

If the engine oil filter can perform its main function well, it will be very useful for extending the service life of the engine. The engine can run smoothly and efficiently for a long time, relying on proper lubrication, as well as preventing pollution and wear. During daily maintenance, regularly changing the engine oil and oil filter can further extend the engine's lifespan. This way, the risk of premature engine failure and the need for expensive repairs can be minimized. In internal combustion engines, oil filters play multiple important roles, and without them, it is not possible.

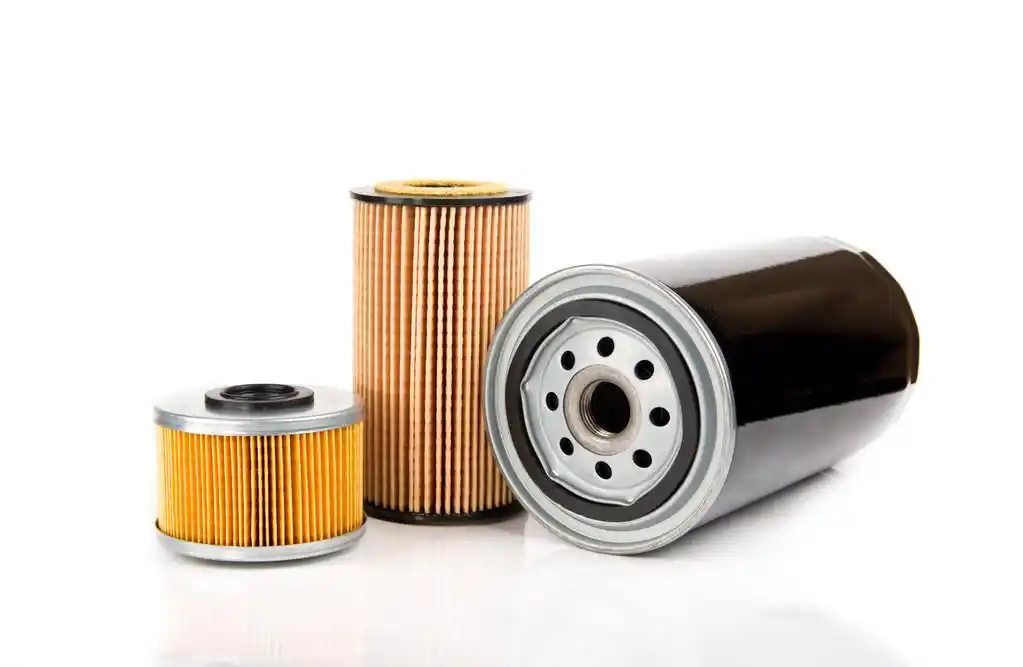

[Product Types]

The cylindrical filter does not have a complete casing and is composed of replaceable filter elements installed in a metal or plastic casing. If you need to replace the filter, just replace the filter element inside without moving the outer shell. Modern cars often use cylinder oil filters, which have many benefits such as reducing waste and potentially lower long-term costs. There is also a magnetic oil filter, which has magnetic components in its filter housing that can suck up metal particles containing iron in the engine oil.

These filters work together with traditional filtering devices to remove metal shavings and small particles generated by wear and tear during engine operation. Magnetic oil filters are usually used on equipment with heavy engine loads, such as construction machinery and mining machinery. Why? Because this thing can prevent components from being worn out too early. Efficient oil filters, as the name suggests, have stronger filtering capabilities than standard filters. They use advanced filtering materials, mostly synthetic materials with gradient density structures, which can effectively capture and retain smaller particles

Modern engines have stricter tolerance requirements, and high-efficiency oil filters are particularly good for this type of engine. It can make the oil cleaner and reduce the risk of engine damage due to small pollutants. Centrifugal oil filters separate pollutants from engine oil by centrifugal force. This type of filter has a rotating drum or disc, which forces the oil inside to quickly turn. When the engine oil rotates, heavy particles are thrown outside the drum and then received in a separate chamber.

Centrifugal oil filters are generally used in industrial and high-performance vehicles. Why? Because it can allow relatively clean engine oil to return to the engine, as well as process large amounts of oil and continuously filter it. The bypass oil filter is an auxiliary filter that works in conjunction with the main full flow filter. Its working method is to distribute a small portion of engine oil into the secondary filtration circuit. The bypass filter is used to remove small particles that may not be caught by the main filter.

[Main purpose]

Oil filters are crucial for the maintenance and performance of internal combustion engines. It mainly ensures that the engine oil is clean and of good quality, which is very important for the smooth operation and long-lasting use of the engine. This article aims to discuss the main functions of engine oil filters, with a focus on how important they are in protecting engine components, saving fuel, reducing emissions, and prolonging engine life. One of the main tasks of an engine oil filter is to remove dirt from the engine oil.

The engine oil sludge is a kind of gel. It will appear when the engine oil is decomposed and contaminated by particles and impurities. Mud will accumulate in many parts of the engine, such as the oil passages and valve mechanisms. Once it accumulates, the oil will not flow smoothly and lubrication will be affected. Over time, engine sludge can cause severe damage to the engine, leading to a decrease in performance. The engine oil filter can remove pollutants and keep the oil clean, which can prevent the formation of sludge and ensure that the oil flows smoothly in the engine, and lubrication is effective.

The key components of the engine are not worn or damaged, and effective filtration of the oil filter is crucial. There are pollutants such as dust and metal particles in the engine oil, which can cause more severe friction and wear on the surface of the engine. The oil filter removes all these pollutants, protecting components such as pistons, cylinders, camshafts, and bearings, extending their service life, and ensuring reliable engine operation. The engine is clean and well lubricated, resulting in higher operating efficiency and improved fuel economy.

The engine oil filter can remove pollutants and maintain normal lubrication, which can reduce friction and mechanical wear inside the engine. With less friction, engine efficiency increases, fuel consumption decreases, and overall fuel economy improves. So, the engine oil filter can reduce fuel consumption and emissions, which is beneficial for the environment. Regularly changing the engine oil and oil filter is crucial for extending the lifespan of the engine.

【 Conclusion 】

The engine oil filter can keep the oil clean and uncontaminated, which can prevent premature wear and tear of engine parts. In this way, the service life of the engine is extended, and there is no need to spend a lot of money on repairing or replacing the engine. Proper maintenance and use of high-quality engine oil filters can make the engine more reliable and durable, saving money and being environmentally friendly in the long run. What sustains the health and performance of internal combustion engines? The role of the oil filter is significant.

They are particularly important for removing pollutants, maintaining proper lubrication, preventing engine sludge, protecting engine parts, improving fuel efficiency, and extending engine life. The normal operation of the engine oil filter is crucial for ensuring smooth engine operation, reducing maintenance costs, and promoting sustainable development in the automotive industry. Understanding the importance of engine oil filters is essential for maintaining engine health and achieving optimal engine performance.

EN

EN