Автоматтык чыпкаларды оптималдаштыруу стратегиясы жана практикасы Кыргызстан

Автоматтык чыпкаларды оптималдаштыруу стратегиясы жана практикасы

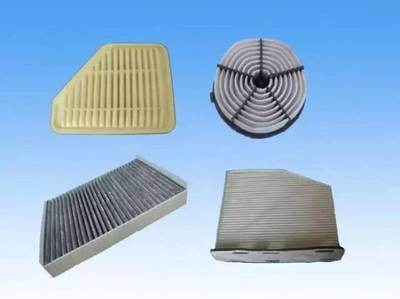

As a key protective component of the engine, the car filter is of great significance in ensuring the performance of the vehicle and extending the service life of the engine. This article will explore in detail how to optimize automotive filters, from multiple aspects such as material selection, structural design, quality control, technological innovation, and market strategy, in order to provide reference for filter manufacturers and the automotive industry.

Optimization of Material Selection

The performance of car filters largely depends on the selection of their materials. Firstly, high-quality filter materials can effectively block impurities and particulate matter while maintaining good breathability. For example, efficient fiber materials can increase the filtration area and improve filtration accuracy. For air filters, using high-quality filter paper or non-woven fabric can significantly improve their filtration efficiency and reduce wear on components such as cylinders and pistons. The oil filter and fuel filter can be made of materials such as filter paper, felt, metal mesh, etc. to ensure the cleanliness of the oil and fuel.

In addition, the materials of the filter housing and connecting components also need to have high strength and fatigue resistance. Materials such as alloy steel, aluminum alloy, and glass fiber reinforced plastic are commonly used to manufacture the housing of air filters to improve their vibration resistance. In the design of oil filters, the use of corrosion-resistant and high-strength materials can ensure the stability of the filter under various harsh working conditions.

Optimization of structural design

The structural design of a filter directly affects its filtration efficiency and performance. Reasonable structural design can optimize airflow, reduce resistance, and thus improve filtration efficiency. Air filters often adopt a multi-layer filtering structure, which can filter particles of different sizes in stages. The oil filter and fuel filter also achieve higher filtration efficiency and lower pressure drop by optimizing their internal structure.

The position of the safety valve is also crucial in the design of oil filters. When a traditional oil filter is clogged, if the safety valve is not properly positioned, impurities on the filter element may flow directly into the engine through the safety valve, causing damage to the engine. Therefore, designing a safety valve between the filter element and the threaded cover plate can effectively avoid this problem, ensuring that the safety valve can open when the filter element is clogged or cold started, directly connecting the inlet and outlet of the oil, and avoiding impurities from entering the engine.

Optimization of Quality Control

Strict quality control is the key to ensuring stable and reliable performance of the filter. Manufacturers need to implement comprehensive quality control measures, strictly controlling every step from raw material inspection to finished product testing. Strict testing and verification are required for key performance indicators such as filtration efficiency, pressure resistance, and vibration tolerance of filters to ensure that each filter meets design specifications.

In addition, regular maintenance and replacement are also important steps to ensure the performance of the filter. Manufacturers should advise users to replace filters on time to avoid excessive use that may lead to a decrease in filtration efficiency. At the same time, strengthening the construction of after-sales service system, providing timely technical support and maintenance services, can also effectively extend the service life of filters.

Optimization of Technological Innovation

With the continuous advancement of engine technology, filter manufacturers need to constantly develop new types of filters to meet new demands. For example, by using more efficient filtering materials and optimizing the structure, the filtration efficiency and service life of the filter can be improved. Introducing intelligent replacement frequency technology, flexibly adjusting the replacement cycle of the filter according to the actual usage of the vehicle, achieving a balance between performance and economy.

In addition, environmental protection processes and technological innovation are also directions that filter manufacturers need to pay attention to. By optimizing smelting and heat treatment processes and introducing environmentally friendly production technologies, not only can filter performance be improved, but the impact on the environment can also be reduced. For example, using stainless steel material and high-efficiency filter paper not only improves the durability of the filter, but also reduces maintenance cycles and overall costs.

Optimization of market strategy

Against the backdrop of increasingly fierce competition in the automotive filter market, manufacturers need to conduct in-depth analysis of the market environment and flexibly adjust their market strategies. By optimizing marketing strategies, improving product quality, strengthening the construction of after-sales service system, and attaching importance to product appearance design and packaging, we aim to enhance the market competitiveness of our products. At the same time, based on market demand and competition, flexibly adjust product prices and develop a price change mechanism throughout the entire lifecycle to better respond to market changes.

In addition, segmenting channel networks and promoting coordinated development between online and offline channels are also effective ways to improve sales performance. Manufacturers need to segment and plan their channel network, clarify the functions and positioning of different channels, in order to enhance end customer stickiness and improve overall sales performance.

эпилог

In summary, the optimization of automotive filters needs to start from multiple aspects such as material selection, structural design, quality control, technological innovation, and market strategy. By continuously improving the performance and reliability of filters to meet market demand, manufacturers can not only enhance the market competitiveness of their products, but also contribute to the automotive industry and environmental protection. In the future, with the continuous advancement of technology and changes in the market, the optimization of filters will continue to advance, bringing more innovation and breakthroughs to the automotive industry.

EN

EN