ইনস্টলেশনের আগে ফিল্টারের গুণমান কীভাবে পরীক্ষা করবেন

**How to check the quality of the filter before installation**

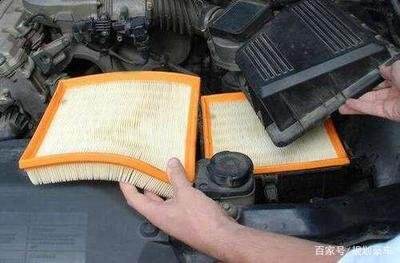

In the process of car maintenance and upkeep, the replacement of filters is very important. As a key component of the car's internal circulation system, the performance of filters directly affects the engine's operating efficiency and service life. Therefore, it is particularly important to strictly inspect the quality of the new filter before installing it. This article will elaborate on how to inspect the quality of filters from multiple aspects such as appearance inspection, functional testing, material analysis, brand and certification, and supplier reputation, in order to ensure that the installed filters can fully exert their filtering effect and ensure the normal operation of the engine.

1、 Check the exterior

Firstly, conduct a visual inspection of the filter. During inspection, attention should be paid to the following aspects:

1. Packaging integrity: Check whether the filter packaging is damaged or squeezed. Packaging is the first line of defense to protect the filter from damage during transportation and storage, and its integrity directly reflects the degree of product protection.

2. * * Check the integrity of the appearance * *: Observe the surface of the filter for contamination, scratches, and damage. These stains may indicate that the filter has been mishandled during production, transportation, or storage, thereby affecting its service life and filtration efficiency.

3. Check the clarity of the identification: Check whether the code, production date, and brand name on the filter are clear and accurate. These pieces of information are important basis for confirming whether the filter meets the requirements of the vehicle.

4. Structural filter integrity: Check whether the outer shell, filter element and other components of the filter are intact and undamaged, and whether the connection parts are firm. Any structural defect may cause problems with the filter during use.

2、 Functional testing

Secondly, conduct a functional test of the filter. This step requires the use of professional testing equipment and environment to simulate the working state of the filter in actual use, verify its filtering effect, pressure loss and other key performance indicators.

1. * * Filtration efficiency test * *: By injecting a fluid containing a certain concentration of impurities into the filter, the change in impurity concentration before and after the filter is measured to evaluate its filtration efficiency. An efficient filter should be able to significantly reduce the impurity content in the fluid.

2. Pressure loss test: Measure the pressure difference between the inlet and outlet of the filter under normal working conditions. Excessive pressure loss may indicate blockage or improper design inside the filter, thereby affecting the engine's power output and fuel economy.

3、 Durability testing

1. Temperature testing:

Place the filter in high and low temperature environments, test its performance at extreme temperatures, and ensure that it can function properly under various environmental conditions.

2. Vibration test:

Simulate the vibration environment during vehicle or equipment operation, test the anti vibration performance of the filter, and ensure that it will not be damaged due to vibration during long-term use.

4、 Material analysis: exploring the essence to ensure safety

Next, conduct a material analysis of the filter. The material of the filter directly determines its key characteristics such as corrosion resistance, high temperature resistance, and sealing performance. Therefore, it is crucial to conduct in-depth research and analysis on the material of the filter.

1. * * Shell Material * *: Check whether the material of the filter housing meets relevant standards, such as whether it has good impact resistance, corrosion resistance, and high temperature resistance. These characteristics are crucial for protecting the internal structure of the filter and ensuring its long-term stable operation.

2. * * Filter Material * *: Analyze the material composition of the filter element, including the filter medium (such as paper, metal mesh, fiberglass, etc.) and supporting structure (such as skeleton, end cap, etc.). High quality filter cartridges should have good filtration performance, strength, and durability to cope with various complex working conditions.

3. * * Sealing Material * *: Check whether the material of the sealing part of the filter is soft, elastic, and corrosion-resistant. Good sealing performance is the key to ensuring the normal operation of the filter and preventing fluid leakage.

.

5、 Supplier reputation: reputation based, worry free cooperation

Finally, assessing the reputation of the filter supplier is also an important aspect that cannot be ignored. Choosing a reputable and attentive supplier can ensure reliable quality and worry free after-sales service for the purchased filters.

1. * * Enterprise Qualification * *: Understand the supplier's enterprise qualification, production scale, and technical strength. Suppliers with a complete production system and strong technical research and development capabilities are more likely to produce high-quality filter products.

2. * * Customer feedback * *: Understand the supplier's market reputation and service quality through customer evaluations, industry forums, and other channels. Customer satisfaction and feedback are important references that reflect supplier reputation and product quality.

3. * * After sales service * *: Inquire about the supplier's after-sales service policies, such as return and exchange policies, warranty periods, technical support, etc. High quality after-sales service can provide customers with more comprehensive protection and support.

In summary, conducting a comprehensive inspection from multiple aspects such as appearance inspection, functional testing, material analysis, brand and certification, and supplier reputation before installing a new filter is a key step in ensuring reliable filter quality and superior performance. The implementation of these inspection measures will help consumers choose the most suitable filter products for their vehicles, providing strong guarantees for the stable operation of the car.

EN

EN