he Influence of Automotive Filter Material on Durability България

The Influence of Automotive Filter Material on Durability

In the automotive industry, filters play a crucial role as key components in maintaining efficient and stable engine operation. The core function of a filter is to filter out impurities in engine oil, fuel, or air, protect the engine from wear and blockage, and extend its service life. The durability of a filter largely depends on the material used. This article will delve into how automotive filter materials affect it! Durability, in order to provide valuable reference for filter manufacturers and consumers.

Overview of Filter Materials

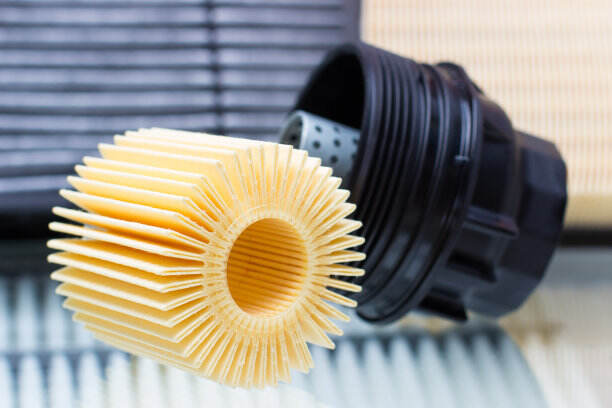

Automotive filters typically consist of a casing, filter element, seal, and connecting components. The shell and filter element are the main structure of the filter, and the selection of their materials directly determines the overall performance and durability of the filter. Common filter housing materials include metal (such as steel, aluminum alloy) and plastic, while filter cartridges are often made of paper, fiber, metal mesh, or composite materials.

The impact of material on durability

1. Shell material

Metal material: The metal shell, such as steel and aluminum alloy, has high strength and corrosion resistance, and can withstand significant pressure and temperature changes. It is suitable for filters in high-pressure and high-temperature environments. The cost of steel casing is relatively low, but the weight is relatively large; The aluminum alloy casing combines the characteristics of lightweight and high strength, making it the preferred choice for high-performance filters.

0 Plastic material: Plastic shells are usually used for lightweight filters, such as air filters. Plastic has good formability and corrosion resistance, and is lightweight, which helps reduce vehicle weight and improve fuel economy. However, the heat resistance and pressure bearing capacity of plastic shells are relatively weak, and careful selection should be made according to the specific usage environment. 2. Filter material

Paper filter element: The paper filter element is made of multi-layer microporous paper, which has high filtration efficiency and good breathability, and is suitable for oil and fuel filters. However, paper filter cartridges have limited oil resistance, heat resistance, and mechanical strength, making them susceptible to damage in harsh environments and requiring regular replacement.

Fiber filter element: Fiber filter element is made of synthetic fiber or natural fiber, such as polyester fiber, glass fiber, etc. Fiber filter cartridges have high filtration accuracy and strength, better oil and heat resistance than paper filter cartridges, and are suitable for filters that work in harsh environments for a long time.

Metal mesh filter element: The metal mesh filter element is woven from metal wire and has high strength and durability, but the filtration accuracy is relatively low. It is usually used for coarse filtration. The metal mesh filter element performs well under high pressure and high temperature, and is suitable for filters under special working conditions.

Composite material filter element; Composite material filters combine the advantages of different materials, such as combining fibers with metal mesh, paper with plastic, etc., to improve the overall performance of the filter. Composite material filter cartridges have high filtration efficiency, strength, and durability, making them an ideal choice for high-performance filters.

3、 Principles of Material Selection

When selecting materials, filter manufacturers need to comprehensively consider factors such as usage environment, cost, and performance requirements. For example, in high temperature and high pressure environments, gold or composite materials with high heat resistance and pressure bearing capacity should be selected; In light vehicles, plastic shells and lightweight filters can be used to reduce the overall weight of the vehicle; In situations where high-precision filtration is required, fiber or composite filter cartridges should be selected.

4、 Durability testing and validation

To ensure the durability of the filter, manufacturers need to conduct rigorous testing and validation of the filter. The testing content includes filtration efficiency, negative force, heat-resistant parts, pressure bearing capacity, corrosion resistance, vibration, and impact testing. Through testing and validation, the performance of the filter in different environments can be evaluated to ensure its stable and efficient operation in practical use.

5、 Conclusion

The durability of car filters is closely related to their material selection. Reasonable material selection can not only improve the performance of filters, but also extend their service life and reduce replacement costs. Filter manufacturers should fully understand the characteristics and performance of various materials, optimize and combine materials according to actual needs, and provide consumers with high-quality filter products and services. At the same time, consumers should also pay attention to the material and performance of the filter when choosing it, to ensure that the selected filter can meet the actual needs of the vehicle.

In summary, the choice of material for automotive filters is one of the key factors affecting their durability. Through reasonable material selection and rigorous testing verification, the filter can ensure optimal performance in practical use, providing continuous and effective protection for automotive engines.

EN

EN