**Изборът на филтри отчита ли влиянието на факторите на околната среда** В съвременната индустрия и ежедневието филтрите са ключово филтриращо устройство, широко използвано в различни области като автомобили, машини, химикали, пречистване на вода и т.н. България

**Does the selection of filters consider the impact of environmental factors**

In modern industry and daily life, filters are a key filtering device widely used in various fields such as automobiles, machinery, chemicals, water treatment, etc. Their main function is to remove impurities from fluids (such as gases or liquids) to ensure the normal operation of the system and extend the service life of equipment. However, the selection of filters is not a simple specification matching, but a complex decision-making process involving multiple factors, among which the impact of environmental factors is particularly critical. This article will explore from multiple dimensions whether environmental factors should be fully considered in the process of filter selection, and analyze in detail their specific impacts.

###1、 The Importance of Environmental Factors

The working environment of filters varies greatly, from extremely cold Arctic regions to hot desert areas, from humid coastlines to dry inland plateaus, each environment presents different challenges to the performance of filters. Therefore, in the selection process, if environmental factors are ignored, it may lead to low efficiency and shortened lifespan of the filter, and even cause system failures, resulting in economic losses and safety risks.

###2、 The influence of temperature

Temperature is one of the key factors affecting the performance of filters. In high-temperature environments, filter materials may deform due to thermal expansion and contraction, affecting sealing performance; At the same time, high temperature can accelerate material aging and reduce the service life of the filter. On the contrary, in low-temperature environments, the medium inside the filter may solidify, clog the filter screen, and affect the filtration effect. Therefore, when selecting, it is necessary to choose filter materials and structures with corresponding tolerance based on the temperature range of the usage environment, such as using special rubber sealing rings that are resistant to high and low temperatures, optimizing the filter structure to reduce the risk of clogging, etc.

###3、 Consideration of humidity and corrosiveness

The presence of humidity and corrosive gases or liquids poses a severe challenge to the metal components and filter screen materials of the filter. Long term exposure to high humidity or corrosive environments can lead to rusting and corrosion of filters, resulting in problems such as filter damage and seal failure. Therefore, when selecting, priority should be given to filters with anti-corrosion and anti rust functions, such as using stainless steel materials, coating protection, or selecting filter materials with excellent corrosion resistance.

###4、 Characteristics and concentration of particulate matter

The characteristics (such as size, shape, hardness) and concentration of particulate matter in different environments directly affect the filtration efficiency and lifespan of the filter. For example, in environments with severe industrial dust, it is necessary to use filters with high filtration accuracy and large dust holding capacity; In areas with strong sandstorms, sand prevention and wear-resistant designs need to be considered. Therefore, a detailed particulate matter analysis of the usage environment should be conducted before selection to ensure that the selected filter can effectively meet the filtration requirements under specific conditions.

###5、 Adaptability between pressure and flow rate

The pressure and flow fluctuations of the working system are also important factors affecting the selection of filters. The filter must be able to withstand the maximum working pressure of the system without damage, while ensuring effective filtration within the specified flow range. In high-pressure or high flow environments, the structural design of the filter needs to be more robust, and the filter material needs to have sufficient strength and stability.

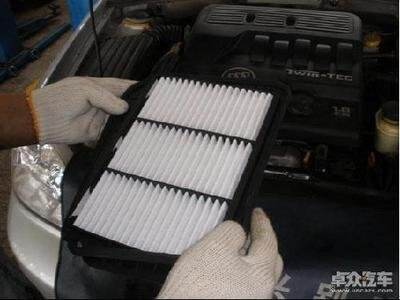

###6、 Convenience of maintenance and replacement

Environmental factors also indirectly affect the maintenance and replacement of filters. For example, in installation locations that are difficult to access or have limited space, it is necessary to choose filter models that are easy to disassemble and maintain. In addition, considering the differences in maintenance cycles in different environments, it is necessary to evaluate the service life of the filter when selecting, to ensure that it can work stably within the set maintenance cycle and reduce inconvenience and costs caused by frequent replacement.

###Извод

In summary, the selection of filters is a complex process that comprehensively considers technical performance, economic cost, and environmental adaptability. Environmental factors, as an indispensable part of it, directly affect the practical application effect and long-term benefits of filters. Therefore, when selecting a filter, it is necessary to comprehensively evaluate the characteristics of the working environment and choose the most suitable filter type to ensure that it can work efficiently and stably in various complex environments, thereby ensuring the safe and reliable operation of the entire system. Through scientific selection and analysis, not only can equipment performance be improved, but the service life of filters can also be effectively extended, maintenance costs can be reduced, and a win-win situation of economic and environmental benefits can be achieved.

EN

EN